today 132

today 132

New design, revolutionary machines, cutting edge technology: the Unimat 09-4x4/4S E³ and the HTW 100 E³ are highly different machines. Both have been fitted with the E³ drive technology and are on show at iaf.

Electric travelling and working operation reduces noise and CO2 emissions.

Since the introduction of the Toyota Prius to the market, at the very latest, hybrid drive technology has become known to the broad public. A lot of progress is being made in the field of electro-mobility. But what about track maintenance machines? Is their benefit verifiable? Does their energy balance produce definite results?

The E³ machines are extraordinary in design and introduce technological further developments.

Since 1953, Plasser & Theurer has been a pioneer in the development of new technologies for track laying and maintenance. The E³ technology proves this yet again. As early as in 2015, this technology was presented to an expert audience at the Convention of ÖVG (Austrian Society for Traffic and Transport Science). In E³ design, the 4-sleeper Tamping Express and the BDS ballast distribution system are either supplied with the energy from the overhead line or powered by the well-proven diesel engine. At InnoTrans 2016, Krebs Gleisbau AG was the first company to receive a universal tamping machine for tracks and turnouts fitted with E³ drive technology: the Unimat 09-32/4S Dynamic E³. Now, the Italian Railway Rete Ferroviaria Italiana (RFI) has also set store by the forward-thinking concept for the Unimat Combi 08-275, a series machine with particular focus on spot maintenance. In mid-2018, the company will receive the first machine from the series in special E³ design for dual operation using 25 kV alternating current or 3 kV direct current. This makes it possible to work on main lines and secondary lines with different power supply systems.

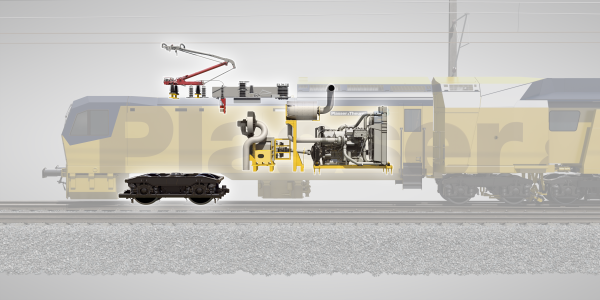

So, what is NEW about the Unimat 09-4x4/4S E³ put on show? Does the new design live up to the technological expectations? Electric travelling and working operation? Travelling has already been possible. The drives, however, are new. The electrical power is supplied to the drive system almost without any losses. At the axles of the power bogies, electrical drive motors transfer the power onto the rail. For the electrical mode of operation, we have electrified our tamping unit without changing the key tamping parameters. Rotary motions are powered by electric motors. All linear cylinders work hydraulically, for instance the squeeze cylinders of the tamping unit or the cylinders of the lifting and lining unit.

What is the added value and the operators' benefit of the further developed E³ technology?

We expect a reduction of the fuel consumption and lower costs for maintenance and machine servicing. Both noise and CO2 emitted during maintenance and on work sites must increasingly be reduced. With the new machines of the E³ series we are prepared for this. In the next six months, we will operate the machines intensively on our premises to gain experiences and to develop the best possible set-up for our customers.

Johannes Max-Theurer

Chief Executive Officer, Plasser & Theurer

“We expect a reduction of the fuel consumption and lower costs for maintenance and machine servicing. Both noise and CO2 emitted during maintenance and on work sites must increasingly be reduced. With the new machines of the E³ series we are prepared for this. In the next six months, we will operate the machines intensively on our premises to gain experiences and to develop the best possible set-up for our customers.

Electric travel mode and working mode

The machine and the drive are supplied with the electricity from the overhead line via the transformer and power converter. The hydraulic components such as the lifting and lining unit or the squeeze cylinder of the tamping unit are supplied by an electrically operated hydraulic unit.

Diesel-electrically powered travel mode and working mode

Acting as a generator, the 600 kW diesel engine generates the energy for the electrical supply of the drive components via the transformer and power converter. In working operation, the work units run just like during electric operation.

The vehicle for the installation and maintenance of the overhead line system on show at iaf is another machine from the E³ series. Its drive technology, however, is different.

Since the early 1980s, we have been offering machines for the installation and maintenance of overhead lines. From the very first day, these machines have significantly contributed to increasing operational safety and installation quality. All these years, our design engineers faced the challenge to find the right solution for the machine drive. During transfer the machine must travel at high speeds to reach the work site as fast as possible. During work, the machine may only emit little noise and CO2 emissions, particularly when working in tunnels, in urban areas or during the night.

The new HTW 100 E³ offers an innovative overall concept: Using the classic diesel drive, the machine travels with 480 kW to the work site as fast as possible. During the journey, the generator charges the battery system. In addition, electric braking generates energy during working travel. On the work site, the HTW 100 E³ is powered electrically using state-of-the-art battery technology. Designed for two 6-hour shifts, the battery capacity can be extended by modules. The battery technology meets the requirements stipulated in the railway standard for onboard lithium-ion traction batteries EN 62928:2016-01. A sophisticated thermal management, in combination with an outside air heat pump, provides for a consistent output, independent of the ambient temperature. It goes without saying that the machine can also be fed via a charging cable.

The HTW 100 E³ performs its work emission-free and quietly, be it in tunnels or in densely populated urban environments. Apart from increasing energy efficiency, the development focussed on improving the ergonomic design. Inside, the new cabin is clearly arranged. The operating controls for travelling and working are clearly separated. The driving desk enables easy operation.

Equipment such as the platform, contact wire holding device, crane, etc. can be preselected using the new, central control box. To control the machine from the crane during working operation, the AFB automatic drive and brake controller, a speed controller, can be used. It controls uniform working travel, so that the operator does not have to use the radio remote control all the time. During measuring runs, it ensures more precise results. In addition, the system increases the service life of the batteries.

Thanks to their design, the working areas provide an increased level of safety. There is no need for the staff to get off the machine. This prevents accidents and avoids unnecessary risks during work.

Without doubt, the HTW 100 E³ enters a new era in overhead line maintenance. Innovative achievements in the E³ technology significantly contribute to the ecological operation of the railways. Ultimately, they benefit the climate goals and our ecosystem.

• Redundant operational reliability

• Increases in the contract volume thanks to new fields of operation, such as in urban areas and tunnels

• Electrical efficiency of up to 94 %

• > 100 € saving per operating hour

• Noise reduced by 10 dBA