today 142

today 142

Increasing safety during operation, saving time, and learning more about the track system: these are important goals that are not always easy to achieve in practice.

The range of methods for diagnosing railway infrastructure is huge. Soon you’ll find yourself immersed in expert knowledge where it’s all about the technical construction, algorithms, formulas, and much more. The actual goal is often lost sight of: providing a basis for decision-making for maintenance and maintenance planning.

Plasser & Theurer has 52 years of experience in measuring technology. During this time, over 200 track inspection vehicles have been built and equipped. In addition to the track geometry, the range of parameters used for analysis has grown steadily. The wave of digitalization gave us additional tools, such as planning, constructing, and maintaining using a digital twin. This is the basis for Building Information Modeling (BIM).

Four diagnostics areas identified

The analysis of the infrastructure can be divided into the following four areas: track (including ballast), rail, turnout, and overhead contact line (including signalling technology). In each area, there are meaningful synergies of parameters that are considered together.

When planning maintenance measures for a track section, there is added value in knowing the reference points in addition to the relative track position. Radargrams or images of the section can be used additionally to better classify exceeded limit values in the course of the geometry. For example, this helps to identify problems in the drainage system that require measures other than simply restoring the geometry of the track in order to remedy them in the long term.

This holistic view is tailored to the area being analysed and is compiled from various signals and input sources.

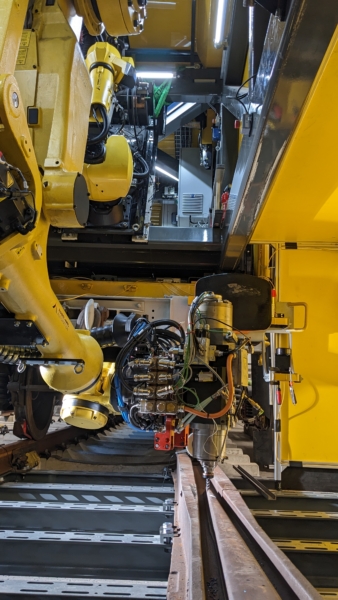

In April 2022, the ROBEL R&D Hub in Freilassing gave rise to ROBEL Rail Automation, a start-up that positions itself as an automation expert for customers and affiliated companies in the Group. In the same year, R2A presented the ROBOT Container at iaf, the world’s first prototype for repairing local rail defects using two fully automated robots working together. This proved the feasibility of a robot-supported, mobile solution.

Our ambition is to achieve very high accuracy and reproducibility of the measurements. Measurements should also be carried out under realistic load, such as the load exerted by the train's rolling wheels. Only this commitment to quality makes it possible to ensure that the measurements are carried out in accordance with standards and that the data infrastructure managers use futher is reliable.

The technology platform has now been further developed to enable fully automated deposition and repair welding for turnouts and to meet the increasing need for maintaining the turnout system. An overall work process is used that has all the necessary functionalities, from inspection and measuring technology to welding and machining technology through to complete digital integration. This provides a resource-saving and reliable alternative to the work currently carried out manually.

Embedded in a preventive maintenance approach by the operator, the service life and performance of the turnout can improve in an environment increasingly characterized by a shortage of skilled staff. The aim of the ROBOT is to reduce track possessions to under four hours with just one person at the control desk and one assistant compared to five or six employees on the track.

Are you interested in developing and testing the robot under real conditions? Get in touch with ROBEL Rail Automation at info@railautomation.com.

Plasser InfraSpector: suitable for every infrastructure

Measurement, inspection, and analysis must be adapted to the area of application. Urban networks have different conditions than high-speed or heavy-haul traffic. Plasser & Theurer offers solutions and services customized to the respective infrastructure.

Plasser InfraSpector, the new generation of measuring solutions, is configured exactly to the requirements of the diagnostics sector. The range of applications extends from integration into existing vehicles or wagons to container solutions, road-rail vehicles, driving trailers without self-propulsion through to fully integrated high-speed track inspection vehicles with self-propulsion.

Turnout inspection as a service

Every turnout in an infrastructure network must be measured regularly as a preventive measure. Doing it by hand with a turnout measuring gauge requires a great deal of manpower and time. The safety aspect complicates things further and negatively impacts operations. Measuring work in turnouts blocks multiple tracks at the same time.

This new form of turnout inspection remedies that because it is no longer necessary to enter the track’s danger zone.

Measuring during regular operations

Experience in many countries has shown that the system is proven in practice. Installed on a track inspection vehicle, such as the EM100VT, measurement takes place in short intervals between trains. In turn, there are no operational restrictions. When measuring multiple turnouts in large railway station facilities, the intervals between trains running at night, where there is less traffic, are sufficient. For example, 61 turnouts were measured on the night of 8 March 2023 in St. Pölten, Austria. That it is not necessary to travel according to a specific pattern is another major advantage. The system recognizes the pass and correctly assigns it to the relevant turnout. Synchronization occurs with the aid of master data and GPS. The entire turnout inspection process takes four minutes on average: an example of an impressive innovation at work.