today 133

today 133

Digitisation adds a new dimension to the partnership of infrastructure operators, contractors and supply industry. Availability and transparency are crucial. Planning preventive measures results in immediate benefit.

Presented at iaf 2017, the scope of the PlasserSmartMaintenance intiative has been growing steadily. It comprises applications that have already been implemented in certain areas. The central platform consists of specific apps with networked cloud solutions and web services. They primarily aim to enable easy access to the relevant data on individual machines, fleets and infrastructure.

Smart apps, online availability and virtual tools have become indispensable in the digital age. SmartMaintenance is a useful tool for decision-makers and machine staff. It enables them to live up to the ever increasing demands. To allow for easy control of complex machine technology – that is our objective.

Track maintenance machines are becoming ever more intelligent. We use the opportunities created by digitisation to increase quality and reliability and to meet the customer’s desire for a higher level of automation and transparency.

Florian Auer

PlasserSmartMaintenance is our contribution to a new era in track construction and maintenance. The “Internet of Machines” is a new approach to the machines for both operators and decision-makers. Using the latest sensor technology and groups of test users, we develop new interfaces for communication, mechanisms of evaluation and digital tools for maximum performance.

Knowing the machine’s position and key information in real time is crucial to operation managers and schedulers. Today, the number of monitoring providers is high. PlasserDatamatic is a standardised interface between GPS data, engine data, filling levels and working parameters.

Soon, we will offer a new version of the PlasserDatamatic – a browser-based user front-end for machine information, reports and analyses. The feedback of our international customers provides the basis for the features of the revised application.

As a single point of access PlasserDatamatic offers:

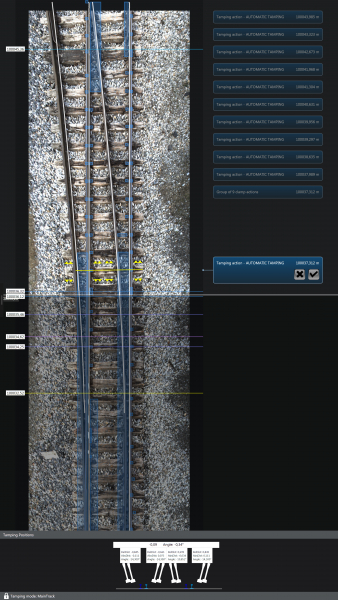

New assistance systems such as PlasserSmartTamping – The Assistant help the operator manage the machine’s operational systems. All work units of a universal tamping machine are controlled by the assistance system during turnout maintenance. The operator only has to confirm the actions the system recommends. This reduces the risk of serious operating mistakes significantly, even though there is always the back-up level of manual interaction.

The new assistance system meets many of our customers’ requirements. Infrastructure operators expect transparency, process reliability and quality in turnout tamping. Machine operators expect a higher level of automation of the tamping process, higher workplace quality and, if possible, a reduction of the staff required. We have taken a step towards these requirements, using the opportunities created by digitisation.

„PlasserSmartTamping – The Assistant“

The digital future of turnout tamping has begun

Fitted with laser scanner, colour camera and rail profile sensors at the front cabin, the machine scans the turnout lying ahead. The assistance software analyses it. The system recognises turnout components and obstacles and recommends corresponding actions for the lifting and lining unit, the additional lifting device and the tamping unit.

These recommendations are shown in the main tamping cabin on the assistance screen on top of the turnout. Green indicates that the system has positively checked the recommendation. The operator confirms the recommendation and activates the pedal. The additional safety feature shows possible irregularities in the recommendation in red. The assistance system operates live, in real time. A separate surveying run and operators in the co-tamping cabin are not needed.

All actions, such as tilting the tamping tines, are carried out by the assistance system. It operates the 3-rail lifting unit, the 4-rail tamping unit, following a tamping plan based on the information provided by the infrastructure operators. A tamping report, issued as an open multilayer pdf, informs about all aspects relevant to quality.

Service and maintenance work ensure a high availability of track maintenance machines. When every minute counts, correct information is crucial to finding the right spare parts immediately. This is why we developed the SmartCatalog (“New after-sales service successfully launched”).

The MMG MachineMaintenanceGuide is a digital service booklet enabling a transparent documentation of machine servicing. In the past, printed service booklets got lost or were completed insufficiently. This made it difficult for operators and manufacturers to assess operating reliability. The MMG clearly documents recommended and implemented measures. Currently, the MMG is only available for tamping units. In the future, the app will be expanded to cover entire machines.

Every maintenance measure generates huge amounts of data on infrastructure, geometry and operational parameters. For our customers, we turn this information into smart data. Life cycle management and assessments according to RAM (Reliability, Availability and Maintainability) require this source.

Operators are under increasing pressure to reduce maintenance costs and time windows, as the availability of the line makes the railway competitive with other modes of transportation. We are already working on the virtual track. It creates new opportunities of cooperation between track maintenance machines and the infrastructure. The quality of the works performed can be immediately inspected by the customer. The number of people in the danger zone is reduced. Works can be inspected from safe offices. The combination of trends and intelligent assessment methods makes it possible to analyse and recommend predictive maintenance actions for the track infrastructure.

Since spring 2018, Plasser & Theurer has been operating the EM100VT. It is the first separate testing vehicle for track inspection. VT stands for virtual track. The vehicle provides a carrier platform for developing and testing new measuring systems, making it an important basis for product development.

We are already working on the virtual track. It creates new opportunities of cooperation between track maintenance machines and the infrastructure.