today 141

today 141

Tamping is a complex process which, despite the most diverse conditions, must always deliver the best possible result. But how do you establish optimum parameters if ballast conditions, lifting values, squeezing times, and tamping depths vary so much? And what does ‟optimum” mean? These are the questions that the TAMP research project has been addressing since 2015. The aim is for the machine to recognize the condition of the ballast, and based on that it can select the parameters for optimum tamping. This is paving the way for full automation and, at the same time, optimum track geometry quality.

For TAMP, fundamental scientific research is certainly not an end in itself. An important short-term objective has been and is to relieve humans through the use of technology and to enable less experienced operators to achieve consistently high-quality results.

The first applications to come out of this research project are already available under the umbrella term Plasser SmartTamping. The Plasser TampingControl, for example, recognizes if a void below a sleeper has not been filled completely and indicates to the machine operator if another squeezing cycle is recommended or required. The Plasser TampingReport also documents the condition of the ballast in addition to other quality-relevant details, making it easier to plan future maintenance operations.

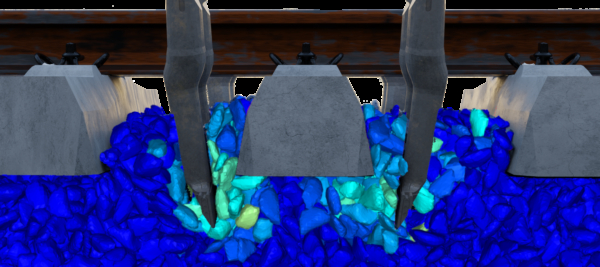

The squeezing process starts after the track panel has been lifted to the desired position, and the vibrating tamping tines have penetrated the ballast.

Filling: The tines move towards each other (squeezing movement) and thus push the ballast together below the sleeper in order to fill the void created during lifting.

Compacting: Once this void is completely filled, further squeezing and the vibration of the tamping tines ensure the optimum compaction of the ballast.

After that, the tamping tines are withdrawn from the ballast. The whole process is repeated multiple times per sleeper, as required.

The data required for this comes from something known as a “reduced measuring system”. It is on the tamping unit and consists of sensors for the hydraulic pressure and angle sensors. Thanks to this fundamental research, the amount of sensors could be reduced to a minimum. This has a positive effect on acquisition costs and servicing requirements.

The results achieved by TAMP so far give hope to achieving further milestones. The “sensing” tamping tines are without a doubt a significant step towards full automation of the tamping process and achieving maximum quality at the same time.

This is an excerpt from a P&T Research article. Click here to read the full article.