today 138

today 138

Plasser & Theurer and Shell have been cultivating a partnership for more than 55 years now. We are also working together to maintain long-lasting, sustainable relationships with our customers. To that end, our absolute focus is on your machines’ optimal functionality, longevity, and the efficiency of their operating costs.

Friedrich Hartmann

Head of Shell Lubricants at Haberkorn Austria

In that respect, extending the service life of your lubricants is key. Before I explain how that’s possible without any risk of machine damage, I would like to provide background information on lubricants and oil changes.

Lubricants are made of base oils and additive packages that are tailored exactly to the requirements of specific machines. The aim is to maintain engines, gearboxes, and components in a condition that is as pristine as possible, allowing them to work efficiently and sustainably. During operation, lubricants and their additives are consumed and age over time. For example, additives that protect component surfaces against wear break down, and oil ageing by-products may form deposits in the machine. In addition, contaminants may enter from outside during operation, or condensation may form as a result of temperature fluctuations. Regular oil changes are necessary: they remove contaminants from the machine and introduce fresh additives.

As a rule, you should use the interval specified by the manufacturer as a guideline. Experience and analyses were used to define this interval, which serves as protection against low-quality lubricants and external contaminants. With our customers in mind, both Plasser & Theurer and we as an exclusive Shell lubricant partner are interested in stretching oil change intervals as much as possible: doing so improves your machine availability, reduces servicing periods, saves costs, and protects the environment.

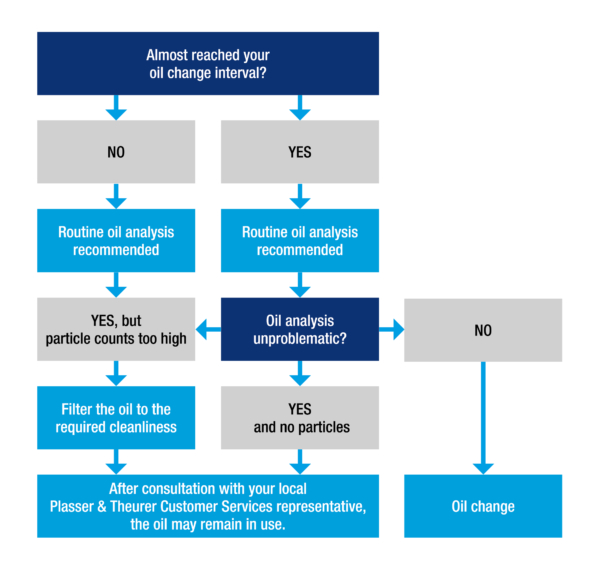

Even at the end of an oil change interval, a high-quality lubricant may still be in excellent condition. That is why Plasser & Theurer and we as a Shell lubricant partner recommend performing an oil analysis at that time to determine the quality of the oil. This analysis gives you detailed information on the condition of your oil and whether you should change it or whether you can keep using it. In addition, it gives you a good idea of your machine’s “state of health”.

For that reason, oil change intervals that have been specified are not set in stone: rather, they are reminders to have your oil analysed. The best-case scenario is that you can significantly extend your oil change intervals.

Please be aware that the worst-case scenario is an oil change that is too late. When a lubricant exceeds its service life and no longer functions as intended, machine damage is inevitable. The resulting costs include repairs, downtime, work delays, and damage to your image; they are far greater than the cost of a planned oil change. When in doubt, a premature oil change is better than one that is too late. Oil analyses allow you to get closer to the end of the actual oil service life without risk and to achieve greater economic efficiency.

Would you like to learn more about oil analyses? Do you have questions about servicing options for your fleet?

Get in touch with us by sending an email to cs@plassertheurer.com

An oil analysis is like a health check for your machine and its lubricant. It can tell you whether it’s possible to extend your oil change interval and what condition your machine is in.

Shell LubeAnalyst is a global Shell service for oil analyses. Contact your local Plasser & Theurer Customer Services representative to learn more about Shell LubeAnalyst and extending oil change intervals.