today 136

today 136

Four new Unimat 08-4x4/4S machines are making Infrabel fit for the digitalisation of turnout maintenance.

During operation at Infrabel and by maintaining different types of turnouts, the assistance system will learn, improve, and reach an even higher level of autonomy. I am very pleased that the Belgian Railway is our first customer in this digital era.

Florian Auer

Director of Technology and Innovation, Plasser & Theurer

Infrabel already has its own impressive fleet of machinery to perform maintenance work on the Belgian railway infrastructure. Now, state-of-the-art machines are about to revamp and modernise the fleet. Again, Infrabel decided to opt for machines by Plasser & Theurer. As of autumn 2020, the new machines will replace one Unimat 108-475 S and three Plasser 08-275 from the past century.

Infrabel states two reasons for making this investment: first, the existing machines have reached their maximum service life. Second, as of 2025, all machines must be compatible with the European Train Control System. The second reason also proved to be an argument for purchasing Plasser & Theurer machines because they meet all the signalling technology requirements.

During one shift, the Unimat 08-4x4/4S will maintain a large number of turnouts that lie parallel to each other. In addition, they will be used to correct spot faults, making them the ideal choice for short track possessions. The universal tamping units of the Unimat 08-4x4/4S have been optimised to meet the special requirements of turnout maintenance. The Split Head technology makes it possible to laterally displace all four unit halves individually. If there is an obstacle in the turnout, the 16 tamping tines simply tilt upwards. Each tamping unit is equipped with two spreading tines. This design enables easy and fast adaptation to difficult situations.

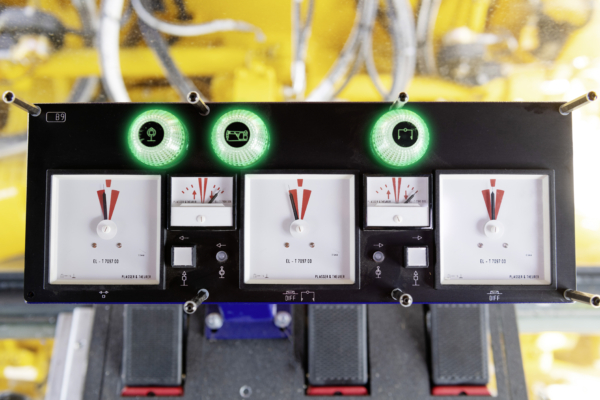

Another special feature of the new fleet is the integrated turnout tamping assistance system: PlasserSmartTamping – The Assistant. Thanks to this system, Infrabel is able to automatically detect obstacles in turnouts. It also serves as a training tool for new staff. The SmartTamping module facilitates the training of operating staff and provides them with immediate feedback on their work.

Digitalising and interlinking relevant data in a smart way build the foundation for optimal infrastructure maintenance. This is how Infrabel can fulfil its tasks for the future and offer their customers the perfect product that is safe, reliable, powerful and, at the same time, cost-efficient.

Annelies Stevens

Manager Switches, Infrabel

The turnout tamping assistant particularly supports less experienced operating staff in achieving a constant tamping result with consistent quality. This is especially important in times where experts retire and know-how is lost. The system retains this know-how and secures reliable operation for infrastructure operators: more than 65 years of experience in tamping technology feed into the digital tamping assistant.

All parameters relevant to quality and work, such as tine position, tamping depth or squeeze time, are available digitally and immediately with an internet connection.

The integrated measuring trolley with inertial measuring unit (IMU) performs surveying at speeds of up to 60 km/h. This leads to considerably improved performance levels.

After tamping, another feature saves time: a rotary laser at the end of the machine measures track spacing. This integrated feature replaces manual control measurement. Besides saving time, it increases worksite safety by eliminating a safety hazard for track workers.

You can find more information on PlasserSmartTamping, artificial intelligence, and smart machines on our website under P&T Research:

It is now possible to survey the actual track geometry at speeds of up to 60 km/h while attaining optimal and accurate measurements. Using automated transfer of measuring data, the SmartALC guiding computer displays the measured values in real-time and calculates the correction values to produce the correct track geometry. The measuring system provides the controlling values needed for quality control already during maintenance. The inertial measuring system, including the well-proven IMU and mechanical gauge measuring, saves time and optimises cost-efficiency of the new fleet.

Meet the intelligent assistant for turnout tamping: the Unimat 08-4x4/4S machines were made for system-supported turnout maintenance. It is possible to control the entire tamping process as well as the lifting and lining unit.

PlasserSmartTamping uses laser technology to measure sleepers, tracks, and obstacles. The data is combined with the data recorded by the camera system. This system is based on artificial intelligence and suggests actions based on railway-specific or national regulations and specifications. The operator always monitors the work and must confirm or correct suggested actions manually before they are carried out.